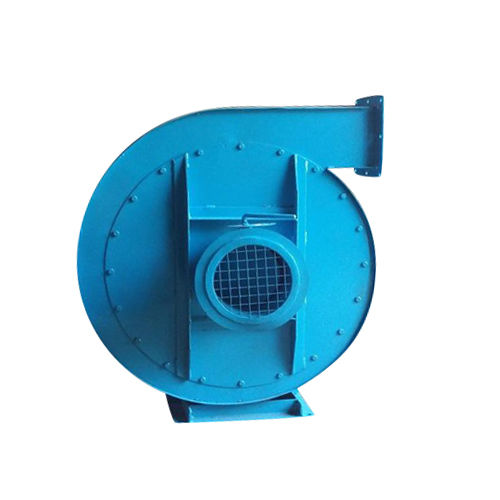

Industrial Blower With Motor

Product Details:

- Pressurization high Pressure

- Product Type Industrial Blower With Motor

- Material Steel

- Application Industrial

- Power Source Electric Blower

- Voltage 240 Volt (v)

- Color Blue

- Click to View more

Industrial Blower With Motor Price And Quantity

- 10 Unit

- 5500 INR/Unit

Industrial Blower With Motor Product Specifications

- Industrial Blower With Motor

- Industrial

- high Pressure

- Steel

- 240 Volt (v)

- Blue

- Electric Blower

Industrial Blower With Motor Trade Information

- Cash Advance (CA)

- 1000 Unit Per Month

- 10 Days

- All India

Product Description

A system that comprises of a motor and a blower unit especially made for industrial uses is referred to as an industrial blower with a motor. The blower, which generates airflow or pressure for a variety of industrial activities like ventilation, air circulation, cooling, or material handling, is powered by the motor.

The following are some essential qualities and traits of industrial blowers with motors:

1. Different motor types, such as AC (alternating current) and DC (direct current) motors, can be used to power industrial blowers. The power supply at hand, the need for speed control, and the particular application are only a few examples of the variables that affect the motor type.

2. Industrial blowers come in a variety of designs, including centrifugal blowers, axial fans, and radial blowers. Each type uses the power of the engine to produce airflow or pressure; each has its unique design and operating principles.

3. Motor Power: The required airflow or pressure for the particular application determines the industrial blower's motor power. Greater airflow or higher pressure can be delivered by motors with more power.

4. Speed Control: Some motorised industrial blowers have the ability to adjust their speed. As a result, the motor speed can be changed to suit the required airflow or pressure. Variable frequency drives (VFDs), adjustable speed drives, and other control techniques can be used to regulate speed.

5. Efficiency and Reliability: In challenging industrial situations, industrial blowers with motors are intended for efficiency and reliability. They are designed to work at their best in challenging environments, at high temperatures, and under demanding situations.

6. Installation and Integration: Industrial blowers with motors are made to be mounted and integrated into a variety of industrial systems with ease. They might have mounting brackets, flanges, or other features for a safe connection to the machinery or ductwork.

HVAC systems, industrial ventilation, dust collection, drying procedures, pneumatic conveying, cooling systems, and many other industries and applications use industrial blowers with motors. The choice of an industrial blower with a motor is influenced by a number of variables, including the necessary airflow or pressure, the operating environment, system compatibility, and energy efficiency concerns.

The particular needs of the application, such as airflow volume, pressure, temperature, noise level, and any unique factors like explosion-proof requirements for hazardous locations, should be taken into account when selecting an industrial blower with a motor. For optimum efficiency and dependability, the motor and blower unit must be properly sized and chosen.

FAQ

1. What exactly is a commercial blower?

Ans - A particular kind of air-moving device used to circulate air in a specific area, such an industrial facility, is called an industrial blower. It is frequently driven by an electric motor and has the ability to cool or heat the immediate area.

2. What are some typical industrial blower applications?

Ans - In order to ventilate the room and move the air, industrial blowers are frequently utilised in industrial facilities. They help push air out and distribute it evenly in air conditioning systems. They can also be used to increase the amount of oxygen in the air and eliminate dust particles from the air.

3. How does a commercial blower function?

Ans - An electric motor is used in an industrial blower to turn a fan blade, which subsequently creates airflow. This airflow is focused through a network of ducts, where it is spread evenly across the room. Depending on the particular design, it might also be feasible to modify the motor's speed in order to regulate the amount of air being moved.

4. How effective are industrial blowers?

Ans - Yes, most industrial blowers are pretty effective. They are built to move a lot of air quickly and effectively at high speeds. They are typically made to make less noise when operating as well.

5. What distinguishes a conventional fan from an industrial blower?

Ans - An industrial blower and a conventional fan are primarily distinguished by the fact that the latter uses an electric motor to move a much larger volume of air. A normal fan typically isn't as efficient as an industrial blower.

|

SAKSHI ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |